|

It is currently Tue Dec 03, 2024 10:51 am |

|

All times are UTC - 7 hours [ DST ] |

|

|

Page 12 of 16 |

[ 477 posts ] | Go to page Previous 1 ... 9, 10, 11, 12, 13, 14, 15, 16 Next |

| Print view | Previous topic | Next topic |

Digger's '69 Build Thread

| Author | Message |

|---|---|

|

Joined: Mon Nov 28, 2016 11:34 am Posts: 808 |

Those are parts are beautiful!

BUT You do not have the required permissions to view the files attached to this post. |

| Wed Apr 03, 2019 1:15 pm |

|

|

Official CCB Member  Joined: Sat Oct 02, 2010 9:41 pm Posts: 1201 Location: Erie |

_________________ 1975 Ranger Edition that I've had longer than I've been without it. |

| Wed Apr 03, 2019 2:32 pm |

|

|

Official CCB Member  Joined: Mon Feb 14, 2011 10:29 am Posts: 768 Location: The MHC |

_________________ Wilma - 71 1/2 Wagon; 3 1/2" WH lift, 1" BL, NP435, Chebby disc front, WH twin stick D20, EFI 302, Cool hood scoop, mucho cancer; purchased in 1990. |

| Wed Apr 03, 2019 3:41 pm |

|

|

Official CCB Member  Joined: Fri Jun 21, 2013 8:53 pm Posts: 1276 |

_________________ Cummins R2.8 diesel, ZF5, AtlasII, HP44/BB9, ARBs, coiled / linked suspension, 37" KO2s, full cage, bumpers, etc. Build Thread: Average 23.5 mpg, Best tank: 25.1 mpg |

| Wed Apr 03, 2019 8:22 pm |

|

|

Moderator  Joined: Mon Nov 15, 2010 5:58 pm Posts: 3906 Location: Henderson, Co |

We better see that boost gauge pegged once.

_________________ Rob 74 Ranger EFI351w, 4r70w, ARB 5.13 9in, ARB 5.13D44, and a bunch of other goodies. Best of all the family memories. 04 Mustang Cobra, KenneBell 2.2 feeding a lot of boost on E85. Tire shredding machine New project: 77 Bronco Ranger, body work and more body work. Very little left of a 72 durango tan explorer sport |

| Thu Apr 04, 2019 6:10 am |

|

|

Official CCB Member  Joined: Wed Sep 29, 2010 10:03 pm Posts: 4371 Images: 0 Location: Parker, CO |

_________________ Best to Date MPG: 26.6 |

| Thu Apr 04, 2019 7:45 am |

|

|

Official CCB Member  Joined: Fri Jun 21, 2013 8:53 pm Posts: 1276 |

_________________ Cummins R2.8 diesel, ZF5, AtlasII, HP44/BB9, ARBs, coiled / linked suspension, 37" KO2s, full cage, bumpers, etc. Build Thread: Average 23.5 mpg, Best tank: 25.1 mpg |

| Thu Apr 04, 2019 9:03 am |

|

|

Official CCB Member  Joined: Fri Jun 21, 2013 8:53 pm Posts: 1276 |

Making a little more progress.

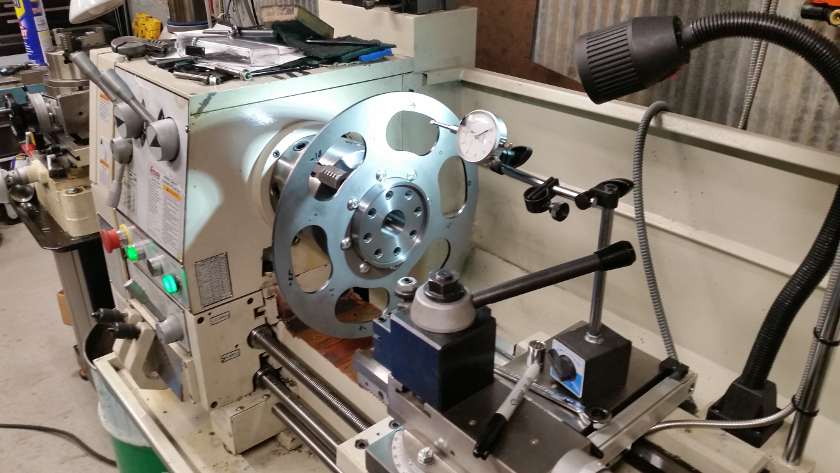

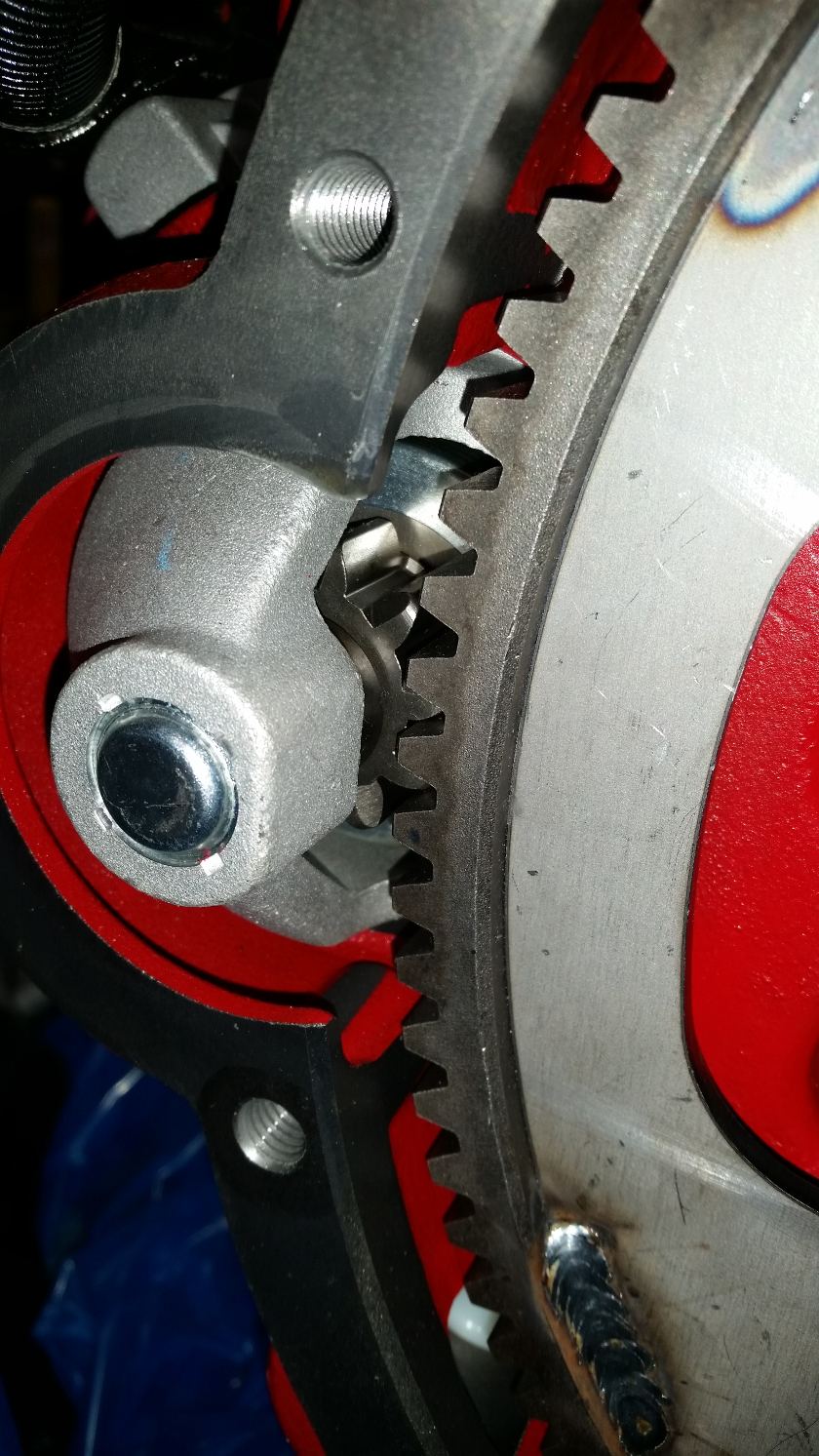

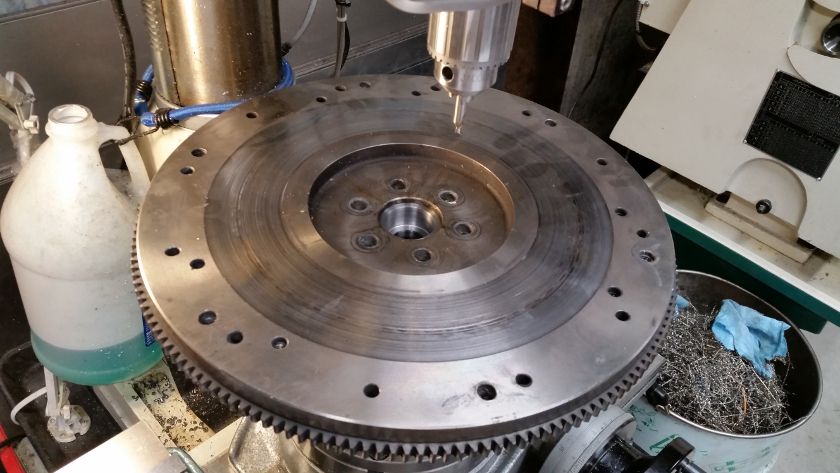

I had a flex plate laser cut for the starter gear. I measured some runout due to heat warpage. I used a dial indicator and a crescent wrench to straighten it out.  With the gear fitted up and restraighten, I covered the lathe and tack welded the gear in place, then pulled it and fully welded it.   Test fitted    _________________ Cummins R2.8 diesel, ZF5, AtlasII, HP44/BB9, ARBs, coiled / linked suspension, 37" KO2s, full cage, bumpers, etc. Build Thread: Average 23.5 mpg, Best tank: 25.1 mpg |

| Thu May 09, 2019 10:44 pm |

|

|

Official CCB Member  Joined: Fri Jun 21, 2013 8:53 pm Posts: 1276 |

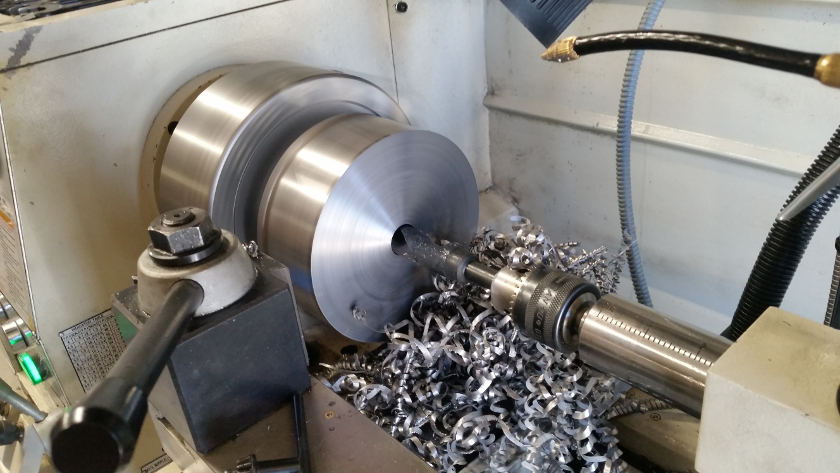

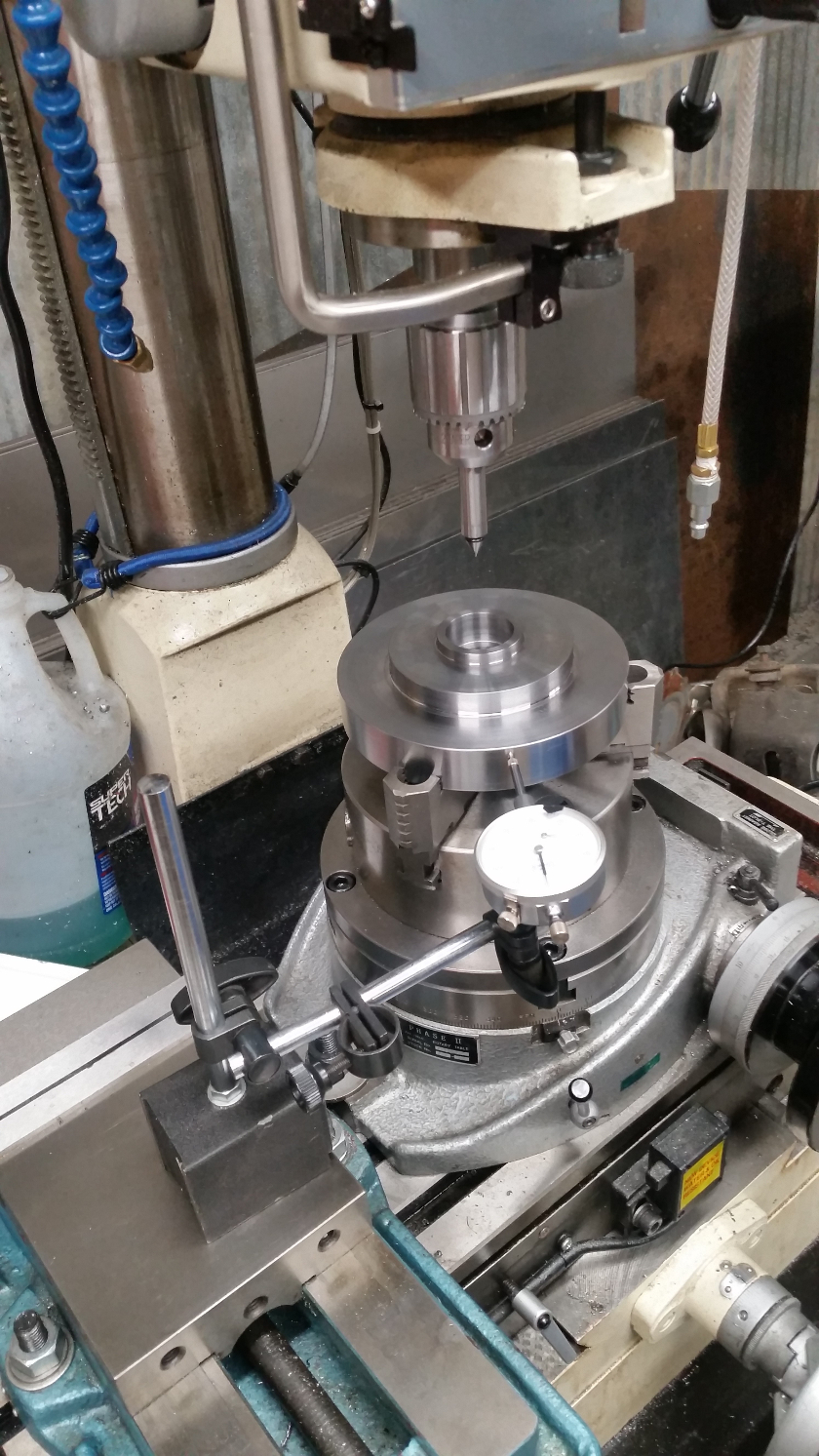

On to the 2nd crank adapter.

Test fitting with the mating part to ensure exact fitment and verify pilot dimensions.  Afterwards, I tested combined runout. It wasn't too bad, .0001" - .0004" depending on which surface was measured. Before drilling holes, I needed to line up the spindle to the rotary table  And check runout on the rotary table  _________________ Cummins R2.8 diesel, ZF5, AtlasII, HP44/BB9, ARBs, coiled / linked suspension, 37" KO2s, full cage, bumpers, etc. Build Thread: Average 23.5 mpg, Best tank: 25.1 mpg |

| Thu May 09, 2019 10:52 pm |

|

|

Official CCB Member  Joined: Fri Jun 21, 2013 8:53 pm Posts: 1276 |

Center drilling the crank holes before drilling. The Ford crank pattern has one hole offset, so I needed to make sure they were all in the right locations

Looks good  Finished up   And one final fitup.   I'm pretty excited to see this finally come together. Even with the tolerance stack up of 5 different interfaces, the flywheel to bellhousing mount face was within .003" of the CAD model. _________________ Cummins R2.8 diesel, ZF5, AtlasII, HP44/BB9, ARBs, coiled / linked suspension, 37" KO2s, full cage, bumpers, etc. Build Thread: Average 23.5 mpg, Best tank: 25.1 mpg |

| Thu May 09, 2019 11:05 pm |

|

|

Official CCB Member  Joined: Thu Oct 25, 2012 9:33 pm Posts: 2460 |

Sent from my iPhone using Tapatalk _________________ 69 Wagon, 351W, Explorer EFI & Serpentine, ZF5, 35" tires, 3.5 SL, 2 BL, WARN 8274 |

| Fri May 10, 2019 12:11 am |

|

|

Official CCB Member  Joined: Sun Aug 04, 2013 2:19 pm Posts: 375 Location: Hudson |

What Eck said

|

| Fri May 10, 2019 4:00 am |

|

|

Official CCB Member  Joined: Wed Sep 29, 2010 10:03 pm Posts: 4371 Images: 0 Location: Parker, CO |

Amazing, love seeing all the adapters in place, that means it’s time to get that thing in the engine bay!

_________________ Best to Date MPG: 26.6 |

| Fri May 10, 2019 5:24 am |

|

|

Official CCB Member  Joined: Sun Oct 16, 2011 7:45 pm Posts: 357 Location: Thornton, Co |

So Cool!

You do not have the required permissions to view the files attached to this post. _________________ TJ "Everyone suspects himself of at least one of the cardinal virtues, and this is mine: I am one of the few honest people I have ever known." F. Scott Fitzgerald 1974 Ford Bronco 3 1/2 inch James Duff lift ,2 inch body lift, 351w Explorer EFI, Viper built c4, Viper built Dana 20 with wildhorses twin stick, Kinder built Dana 44 with 4.56 gears disc brakes aussie locker and knuckle over conversion, Kinder built 9 inch with grizzly locker 31 spline axles and 4.56 gear |

| Fri May 10, 2019 7:21 am |

|

|

Joined: Tue Apr 10, 2018 10:01 am Posts: 69 |

Jesse,

I’ve been following your progress...very exciting stuff here. I cannot wait to see this thing driving w/ the turbo diesel  Nice craftsmanship!! Hank |

| Sat May 11, 2019 12:23 am |

|

|

Official CCB Member  Joined: Sun Oct 10, 2010 12:04 am Posts: 6198 Images: 0 Location: Lakewood |

Wow. Blown away.

|

| Sat May 11, 2019 8:29 am |

|

|

Official CCB Member  Joined: Thu Dec 23, 2010 6:55 pm Posts: 809 Location: Broomfield |

What all these guys said. That is a trick setup to be sure. Hope to see it running in the near future.

_________________ Bob - Turning hydrocarbons into noise since 1970 Spiritual owner of the now Zoso mobile (1974 Bronco Ranger - EFI 351W-4R70W-ARB front and rear-STC softtop- High Country hood-3 1/2" WH lift- Cross inboard rear shock mnt- Duffs bumpers- Warn 8274- 33's- Cheby disc conversion) |

| Thu May 23, 2019 5:28 pm |

|

|

Official CCB Member  Joined: Thu Nov 11, 2010 10:36 am Posts: 5984 Location: California |

No update in 3 months?? I assume that is because you've been cruising this thing burning diesel??

_________________ 1973 Bronco, 351 SEFI, Locked, discs, 35's ZF-5spd and Atlas 4spd. 235:1 Crawl Ratio. It may be ugly, but it's slow. http://www.ucora.org |

| Thu Aug 29, 2019 9:33 am |

|

|

Joined: Sun Jul 08, 2018 9:04 am Posts: 113 Location: Denver, CO |

Just got done spending a week with 3 R2.8 rigs, really cool motor throwing down impressive mileage on 38s.

Sent from my iPhone using Tapatalk |

| Wed Sep 04, 2019 12:43 pm |

|

|

Official CCB Member  Joined: Sun Oct 10, 2010 5:36 pm Posts: 3980 Location: Roxborough Park, Colorado |

I missed these recent updates.......impressive doesn’t even begin to cover it !

Nice work _________________ 1977 Sport, 351w OBDII EFI motor, 4R70W auto, 4:88 gears, ARB lockers, 3.5" suspension, 33" tires. |

| Wed Sep 04, 2019 7:23 pm |

|

|

Official CCB Member  Joined: Fri Jun 21, 2013 8:53 pm Posts: 1276 |

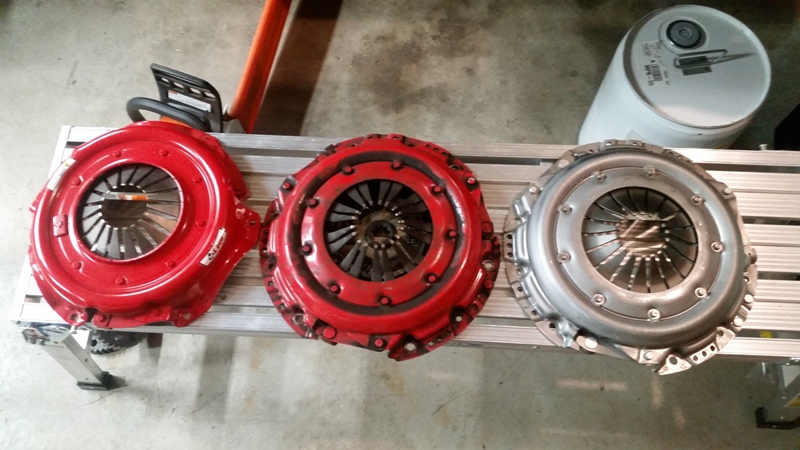

Whew, 5 months since my last update!

Needless to say, there has been A LOT going on in my life. Too much for details. Other things needed more attention than the Bronco. Summer came and went before I knew what happened. Things are getting back to normal and the push on the Bronco has resumed. Going back to early May, I ordered a clutch for the R2.8. Nothing special, just another McLeod like the unit I had before. I could have re-used the old one, but it was grooved and I wanted fresh parts. Well that started another fiasco similar to the intake manifold problem I had last summer that started this whole engine swap. I was getting a pit in my stomach at the prospect of waiting months for back ordered parts. I was able to track down a different clutch kit and order it. Well it showed up and it was definitely not designed for a hydraulic throw out bearing. So I jumped brands and bought a Luk clutch kit that seems like it will fit the build. Nothing fancy, just a standard clutch with a little extra holding power.  Laying all three clutches side-by-side, you could see the difference in the spring fingers. The new McLeod clutch fingers did not extend as far towards the crank centerline and the hydraulic throwout bearing wanted to pass right through. Additionally, the distance from pressure plate to top of clutch fingers was slightly different.    Ironically, all three pressure plates were stamped "Luk". With new clutch in hand, about mid-June, I dis-assembled the adapter set and fit the clutch.  The stack of parts is pretty tall, not ideal, but it should work fine. Weight-wise, its heavy. Both the stock Ford 351 flywheel and the Cummins flywheel hover around 25lbs. The stack with adapters is pushing 45lbs. However, the majority of that weight is much closer to the crank centerline, so additional rotational inertia is minimized. Add the clutch set in the mix and I don't think the impact will be too bad. Some guys have stacked two flywheels weighing over 60lbs with adapters, so I'll be okay. The main reason for pulling the adapter was to check balance on my flex plate. The adapters themselves don't really need a balance, as they are very true and closer to crank centerline. Maybe someday when I build my dynamic balancer, I'll throw in the whole thing on. To check balance on the flex plate, I borrowed a motorcycle wheel balancer. Since the flexplate has a high diameter:length ratio, a static balance is good enough. A few of us at work played with it for a while, but the unit was very true and well balanced, so no weight was removed. We double checked our selves by adding weight at different points to verify the unit was truly balanced with the weight removed.  _________________ Cummins R2.8 diesel, ZF5, AtlasII, HP44/BB9, ARBs, coiled / linked suspension, 37" KO2s, full cage, bumpers, etc. Build Thread: Average 23.5 mpg, Best tank: 25.1 mpg Last edited by Digger on Thu Oct 17, 2019 12:41 am, edited 1 time in total. |

| Wed Oct 16, 2019 11:40 pm |

|

|

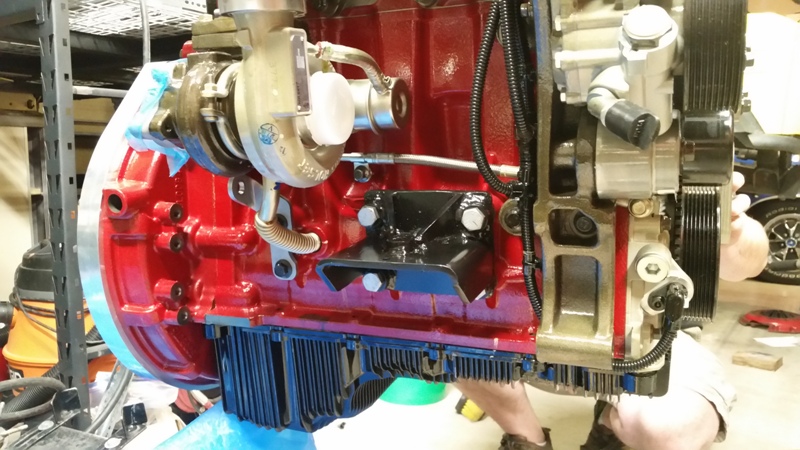

Official CCB Member  Joined: Fri Jun 21, 2013 8:53 pm Posts: 1276 |

Thanks to the CAD model Bronco, I knew going in that the Diesel Oxidation Catalyst (DOC) would not fit between the engine and frame rail. I do intend to keep it and maintain the emission equipment, but it will need to be moved downstream a bit. Originally I planned to use a different turbo exhaust elbow from another 2.8 ISF application, but after studying the CAD model, decided it would be easier to route the exhaust like the passenger side of the 351. There was no off-the-shelf turbo outlet for this, so I drew up a flange in SolidWorks and printed out the template.

Comparing it to the old turbo outlet, it looked correct. A friend of mine cut the flange out on his waterjet. I neglected to get a picture, but it fit perfect. More on that later when I build the exhaust.  With flexplate balance confirmed, it was time for the FINAL assembly. I installed the pilot bearing. Fitment was very good.  I researched and calculated all the torque specs based on known tables and my experience at work with bolt testing. It's pretty interesting stuff if you want to "dork out" for a while. Bolt finishes have an impressive impact on torque specs. All bolts were loctite'd and torqued down, then marked.  Clutch installed:    Before attempting to install the engine, I pulled my spare ZF-5 to verify the transmission will bolt up without issue. It went pretty smoothly, but the transmission would not slide all the way together with the engine adapter. Fearing the worst, I pulled the clutch and re-assembled it, taking great care to center up the friction disc. Still a No-Go. The transmission did not want to slide the last 1/8". I pulled it apart again, but removed the clutch. BOOM, transmission slide right into place. OKAY, now I know it's not the adapter or pilot bearing. I played with the clutch some more and determined the input shaft just really fits tight on the friction plate splines. A minor amount of help from the transmission mounting bolts and the two pulled right into place.  It was really exciting to see the two mated up for the first time!   _________________ Cummins R2.8 diesel, ZF5, AtlasII, HP44/BB9, ARBs, coiled / linked suspension, 37" KO2s, full cage, bumpers, etc. Build Thread: Average 23.5 mpg, Best tank: 25.1 mpg Last edited by Digger on Thu Oct 17, 2019 12:47 am, edited 1 time in total. |

| Wed Oct 16, 2019 11:57 pm |

|

|

Official CCB Member  Joined: Fri Jun 21, 2013 8:53 pm Posts: 1276 |

With a free Saturday, I headed over to U-Pull-n-Pay to scout for some parts. I ended up pulling the air filter box from a V8 Explorer of all applications.

I'll need to fabricate a hose to flange adapter to replace the MAF, but that will be okay.  Back home, I spent a few evenings researching motor mounts. I wanted to re-use the existing frame mounts and MAYBE OEM motor isolators. But it just wasn't going to work. SO, I looked around and discovered most Cummins swap guys are using canister type isolators with threaded studs protruding from each end. It's a straight-forward way to mount the engine. My goal is to use as many OEM parts as possible to improve service-ability. The canister-type mounts have been used by many brands, but it turns out Ford used them on 300 I6's in the last 80s/early 90s. So a trip to the parts store and I bought a set. After modeling them up in Solidworks, I imported them into the big model and began designing the mounting brackets. This took a few evenings. In the end, I tried to mimic a cast bracket with a weldment. I ran some stress analysis on the brackets and tweaked them a bit, but in the end I have brackets that will withstand a 4G vertical loading with a 1.5 safety factor. 4G was chosen because that is near the upper limit of the suspension brackets before deformation could start to occur. I've hit 3Gs a couple of times and the spring buckets were designed with 5Gs in mind. Back in the garage, starting with raw stock:  I bent up the brackets and turned the mounting bosses:  Drilling holes:  Welded up. Certainly not my best work, but functional:  Painted and isolators thrown on:  On to the frame brackets:   Finished product:  _________________ Cummins R2.8 diesel, ZF5, AtlasII, HP44/BB9, ARBs, coiled / linked suspension, 37" KO2s, full cage, bumpers, etc. Build Thread: Average 23.5 mpg, Best tank: 25.1 mpg |

| Thu Oct 17, 2019 12:15 am |

|

|

Official CCB Member  Joined: Fri Jun 21, 2013 8:53 pm Posts: 1276 |

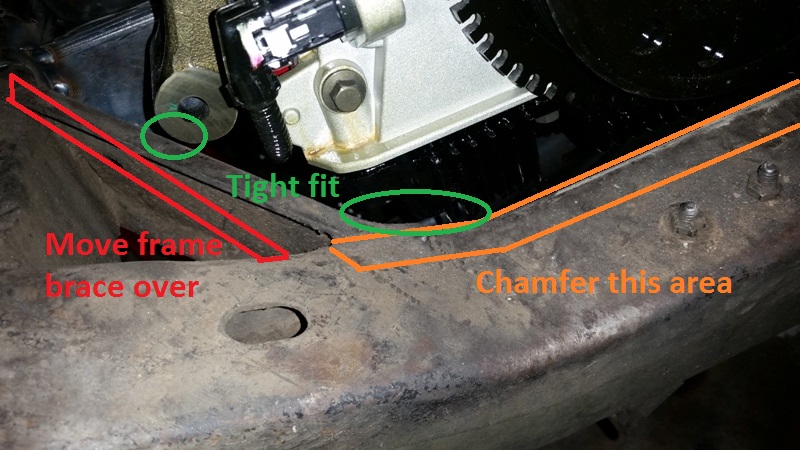

Tonight, my friend came over and we began the 1st engine fitup. First up was getting the Cummins off its shipping pallet:

Then we bolted up the motor mount brackets for the first time. They fit like a glove. CAD + CNC = AWESOME   IN YOU GO!  A LOT occurred in this time-frame. We removed the clutch to speed the install. A load leveler would have helped, but our loaner unit disappeared with another friend, so we made due. Fit going in was tight. I needed to pull a few things out of the way, but they needed to go anyway. I was floored, the CAD model match nearly perfectly. The hundreds of hours spent modeling the frame, body and suspension was paying off. We knew every place to look for clearance issues and everything was as the model predicted. It is a tight fit to the firewall, fenders and brake booster/master cylinder, BUT it does fit.  After a beer break and tacking the frame brackets in place, we spent an hour comparing the model to the real deal, checking clearances and looking for problems.     The power steering inlet may need to be moved or clearance:  The CAD model predicted a fit issue with these brackets. It looks like they need to go:  Crossmember clearance was another anticipated issue. Some trimming and sculpting will have to occur here:  One area that showed a problem was hood clearance. I was a little unsure if this was accurate, but as it turned out, we can't quite close the hood fully:  This was the worst problem, but not the end of the world. _________________ Cummins R2.8 diesel, ZF5, AtlasII, HP44/BB9, ARBs, coiled / linked suspension, 37" KO2s, full cage, bumpers, etc. Build Thread: Average 23.5 mpg, Best tank: 25.1 mpg Last edited by Digger on Thu Oct 17, 2019 12:52 am, edited 1 time in total. |

| Thu Oct 17, 2019 12:30 am |

|

|

Official CCB Member  Joined: Fri Jun 21, 2013 8:53 pm Posts: 1276 |

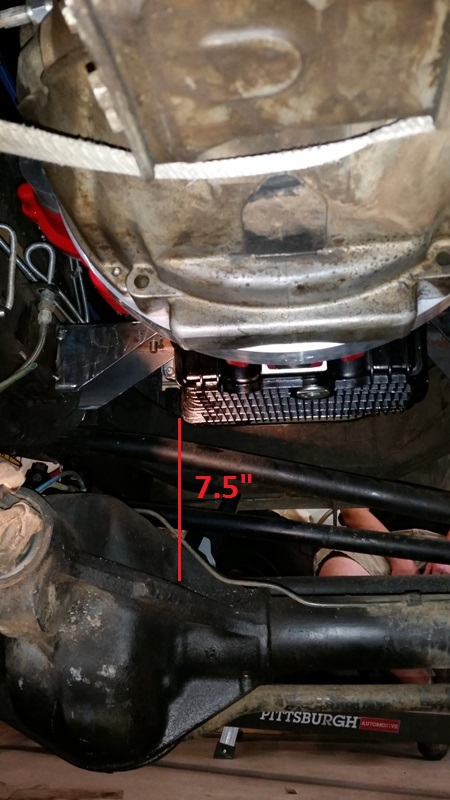

One happy result was the axle clearance. Unlike the 351 with Milodon oil pan, the axle completely misses the Cummins pan. They pass right by each other, instead of one gloving over the other. Now this only works because I have full width axles, placing the differential 3" to the driver's side. Otherwise, uptravel would be severely limited. As it is though, I have 7.5" of upward clearance.

The shape of the oil pan is much better than the Windsor block stuff. Trackbar and drag link clearances still look good. And I'm excited to have a drain plug that points straight down instead of dumping on the axle or crossmember. It's the little things in life...  Buttoned up for the first time in nearly a year:  Misc shots:   Next steps are to pull the engine back out, weld up the frame brackets, modify the crossmember, clean up the engine compartment and replace the steering column. _________________ Cummins R2.8 diesel, ZF5, AtlasII, HP44/BB9, ARBs, coiled / linked suspension, 37" KO2s, full cage, bumpers, etc. Build Thread: Average 23.5 mpg, Best tank: 25.1 mpg |

| Thu Oct 17, 2019 12:38 am |

|

|

Official CCB Member  Joined: Thu Nov 11, 2010 10:36 am Posts: 5984 Location: California |

So much amazingness!!! I wish I could be there to help you thru this, or at least hand you beers!!

_________________ 1973 Bronco, 351 SEFI, Locked, discs, 35's ZF-5spd and Atlas 4spd. 235:1 Crawl Ratio. It may be ugly, but it's slow. http://www.ucora.org |

| Thu Oct 17, 2019 9:09 am |

|

|

Joined: Mon Nov 28, 2016 11:34 am Posts: 808 |

Glad to here you've been working on the build, the motor/fab work is awesome!

|

| Mon Oct 21, 2019 6:21 am |

|

|

Official CCB Member  Joined: Thu Dec 23, 2010 6:55 pm Posts: 809 Location: Broomfield |

Very nice. It's cool to see this build progress. Can't wait to see it firsthand.

_________________ Bob - Turning hydrocarbons into noise since 1970 Spiritual owner of the now Zoso mobile (1974 Bronco Ranger - EFI 351W-4R70W-ARB front and rear-STC softtop- High Country hood-3 1/2" WH lift- Cross inboard rear shock mnt- Duffs bumpers- Warn 8274- 33's- Cheby disc conversion) |

| Sun Nov 17, 2019 10:17 am |

|

|

Official CCB Member  Joined: Wed Sep 29, 2010 10:03 pm Posts: 4371 Images: 0 Location: Parker, CO |

So excited to see progress on this, do you have an idea of when you think it’ll be on the road?

Also, did you leave the transmission in the same position that it was with the SBF? _________________ Best to Date MPG: 26.6 |

| Thu Dec 05, 2019 5:29 pm |

|

|

Official CCB Member  Joined: Fri Jun 21, 2013 8:53 pm Posts: 1276 |

Not sure on timing. I'm down to plumbing and wiring, but there is a lot of details there and I'm hitting a lot of road blocks with this small engine compartment.

Transmission, transfer case and driveshafts are all exactly where they were. They didn't even get disconnected. The R2.8 with my adapter is the same length at the 351W and fits best in the V8's former position in the engine compartment. The bellhousing face in the same on one end and the crank accessory pulley is in the same place on the other end. _________________ Cummins R2.8 diesel, ZF5, AtlasII, HP44/BB9, ARBs, coiled / linked suspension, 37" KO2s, full cage, bumpers, etc. Build Thread: Average 23.5 mpg, Best tank: 25.1 mpg |

| Sun Dec 08, 2019 4:45 pm |

|

|

|

Page 12 of 16 |

[ 477 posts ] | Go to page Previous 1 ... 9, 10, 11, 12, 13, 14, 15, 16 Next |

|

All times are UTC - 7 hours [ DST ] |

Who is online |

Users browsing this forum: No registered users and 4 guests |

| You cannot post new topics in this forum You cannot reply to topics in this forum You cannot edit your posts in this forum You cannot delete your posts in this forum You cannot post attachments in this forum |